Packaging Bag Manufacturing Process

How Bona Conduct Packaging Orders

The production process for packaging bags at Bona, a company specializing in custom packaging solutions, is meticulously structured to ensure quality and efficiency from start to finish.

STEP 1

Consultation

The process begins with a thorough consultation to understand the customer’s needs regarding design, material, size, and specific packaging requirements. This step ensures that the final product perfectly aligns with the client’s expectations and product specifications.

STEP 2

Design and Prototyping

Based on the initial consultation, custom designs are created. We offer options for physical and digital prototypes, allowing clients to visualize their packaging before it goes into production. This stage may involve several iterations to refine the packaging design.

STEP 3

Material Selection

Choosing the right materials is crucial for both functionality and aesthetics. We provide a range of materials including eco-friendly options like biodegradable and recyclable materials, as well as specialized materials for barrier protection, depending on the product’s needs.

STEP 4

Printing and Decoration

Bona utilizes advanced printing techniques such as digital, gravure, and silk screen printing to achieve high-quality graphics and text. This step also includes options for special finishes like matte, glossy, or metallic effects, as well as features like windows, zippers, and tear notches.

STEP 5

Lamination

To enhance the strength and barrier properties of the packaging, multiple layers of material are laminated together. This is especially important for products that require extra protection against moisture, oxygen, or light.

STEP 6

Cutting and Shaping

Once laminated, the material is cut and shaped into the desired bag type, such as stand-up pouches, flat-bottom bags, or gusseted bags. Precision machinery ensures that each bag is consistently manufactured to exact specifications.

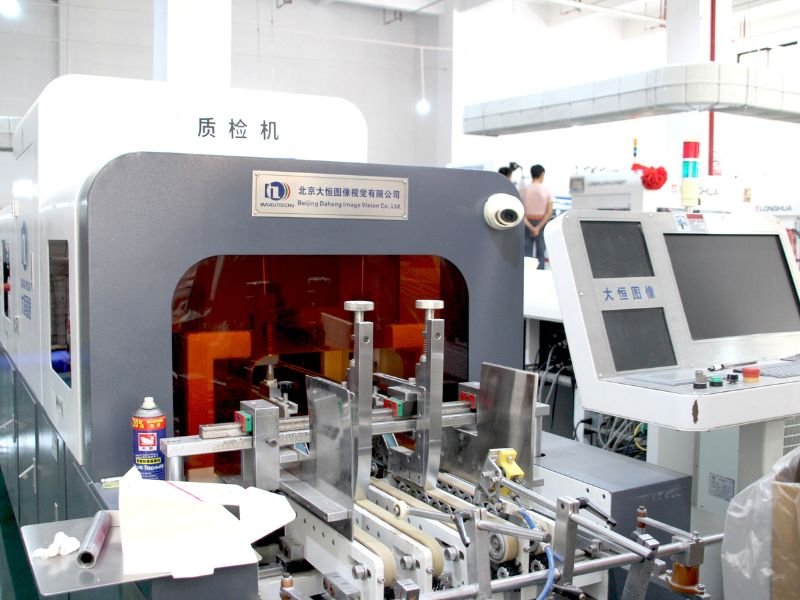

STEP 7

Quality Control

Throughout the production process, we conduct rigorous quality checks to ensure that every packaging bag meets the company’s high standards as well as customer expectations. This includes checks for print clarity, seal integrity, and overall durability.

STEP 8

Packing and Shipping

The finished bags are carefully packed and prepared for shipping. We manage logistics to deliver products directly to customers or distribution centers, offering support for various shipping options and terms like DAP, DDP, CIF, and EXW.