Are you struggling to find the best printing technique for your packaging bags? With so many options available, it’s easy to feel overwhelmed. But choosing the right method is crucial for your brand’s visibility and success. Whether you’re a small business owner or a packaging expert, understanding these techniques can save you time and money while ensuring high-quality results.

The best printing techniques for packaging bags include flexographic printing, rotogravure printing, digital printing, and screen printing. Each method has its advantages and is suitable for different types of materials and designs. By selecting the right technique, you can achieve vibrant colors, sharp details, and durable prints that enhance your product’s appeal.

But why should you care about different printing techniques? Simple: the right choice can significantly impact your brand’s perception and customer satisfaction.

Why Choose Flexographic Printing for Your Packaging Bags?

Flexographic printing is a popular choice due to its versatility and efficiency. It uses flexible relief plates to transfer ink onto a variety of materials, including plastic, foil, and paper. This method is ideal for long runs and high-volume production. It delivers high-quality prints with minimal waste, making it an economical option for businesses.

Flexographic printing is known for its speed and cost-effectiveness. It’s particularly useful for large orders where maintaining consistent quality is crucial. This technique also allows for the use of a wide range of inks, including water-based and UV-curable inks.

Is Rotogravure Printing Worth the Investment?

Rotogravure printing offers exceptional quality, making it perfect for detailed and complex designs. This technique uses engraved cylinders to transfer ink onto the packaging material. It’s highly efficient for large-scale production, providing consistent results with rich, vibrant colors.

While the initial setup cost for rotogravure printing can be high, the long-term benefits outweigh the expense. This method is ideal for high-volume orders and products requiring premium packaging. It ensures that every print is sharp, detailed, and of the highest quality.

When Should You Use Digital Printing for Packaging Bags?

Digital printing is a versatile and cost-effective solution for short runs and customized designs. It involves printing directly from a digital file onto the packaging material. This method is perfect for businesses that need quick turnaround times and shorter print runs.

One of the main advantages of digital printing is its ability to produce high-quality images with intricate details. It’s also excellent for personalized packaging, allowing for unique designs without the need for printing plates. This flexibility makes it a popular choice for limited edition products and special promotions.

How Does Screen Printing Compare to Other Techniques?

Screen printing is a traditional method that remains popular for certain applications. It involves creating a stencil (or screen) and using it to apply layers of ink on the packaging material. This technique is particularly effective for printing on non-flat surfaces and producing bold, opaque colors.

Screen printing is ideal for simple designs with fewer colors. It’s highly durable, making it suitable for packaging that needs to withstand harsh conditions. However, it’s not as efficient for complex designs or high-volume orders compared to flexographic or rotogravure printing.

What Factors Should You Consider When Choosing a Printing Technique?

When selecting a printing technique, consider the following factors:

- Volume: For large orders, methods like flexographic or rotogravure printing are more cost-effective.

- Design complexity: Detailed and intricate designs benefit from rotogravure or digital printing.

- Material type: Ensure the printing method is compatible with your packaging material.

- Budget: Balance the initial setup costs with long-term production needs.

- Turnaround time: Digital printing is best for quick turnaround times and short runs.

Each printing technique has its strengths and limitations. By understanding your specific needs, you can choose the method that best aligns with your production goals and budget.

What Are the Environmental Impacts of Packaging Bag Printing?

Sustainability is a growing concern in the packaging industry. Different printing techniques have varying environmental impacts. Flexographic printing, for instance, uses water-based inks that are less harmful to the environment. Digital printing produces less waste compared to traditional methods since it doesn’t require printing plates.

It’s essential to consider the environmental footprint of your chosen printing method. Look for options that use eco-friendly inks and recyclable materials. Implementing sustainable practices not only benefits the planet but also enhances your brand’s reputation among eco-conscious consumers.

How Can Printing Techniques Enhance Brand Visibility?

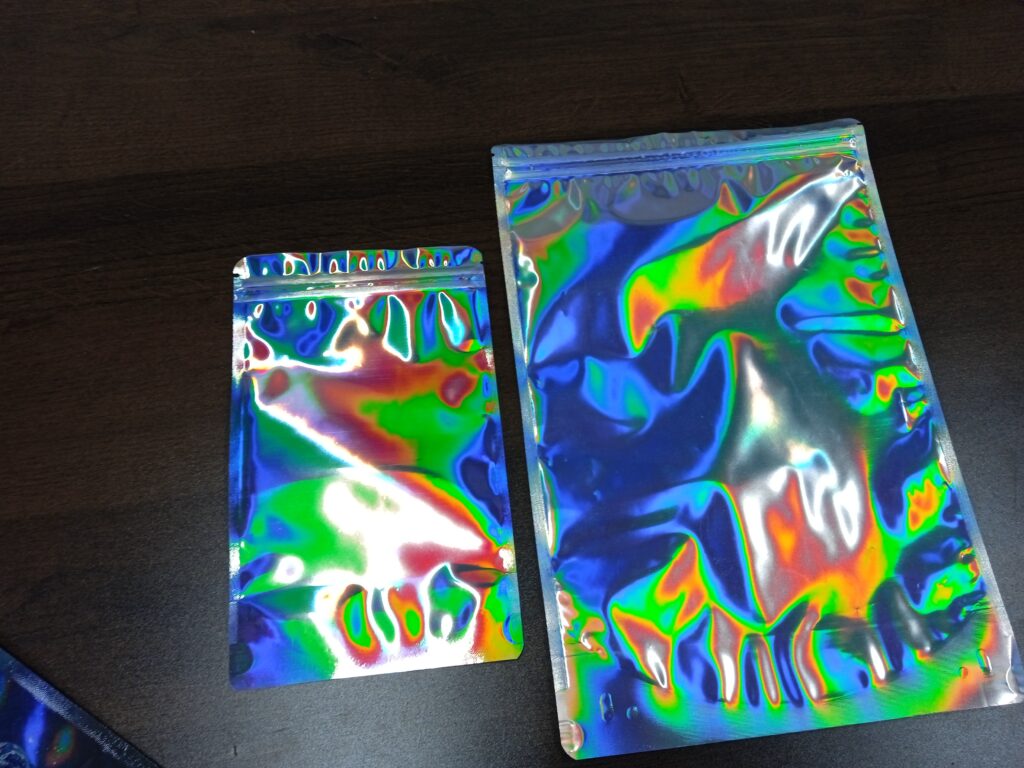

High-quality printing techniques play a crucial role in brand visibility and consumer perception. Vibrant colors, sharp details, and durable prints can make your packaging stand out on the shelves. This visual appeal directly influences purchasing decisions and customer loyalty.

Investing in the right printing technique ensures that your brand’s message is communicated effectively. Whether through eye-catching graphics or clear branding elements, the quality of your packaging reflects the quality of your product. Consistency in printing also helps in maintaining brand identity and recognition.

Conclusion

Choosing the right printing technique for your packaging bags is vital for achieving the desired quality and efficiency. Flexographic printing is great for large volumes, rotogravure for detailed designs, digital for quick and customized prints, and screen printing for bold and durable results. Consider your specific needs, budget, and environmental impact when making your decision. By selecting the appropriate method, you can enhance your product’s appeal and strengthen your brand’s presence in the market.